Lusin Clean 1010

Code: LU1010

Description - Lusin® Clean 1010 is a ready to use purging compound that is specially developed for the processing of PMMA. The purging compound consists of high quality thermoplastic resins as well as highly efficient cleaning additives and does not contain abrasives. The product is completely miscible with PMMA and does not generate any milky traces.

Recomended For- PMMA

Tempreture Range - Lusin® Clean 1010 can be used at processing temperatures up to 300°C (572 °F).

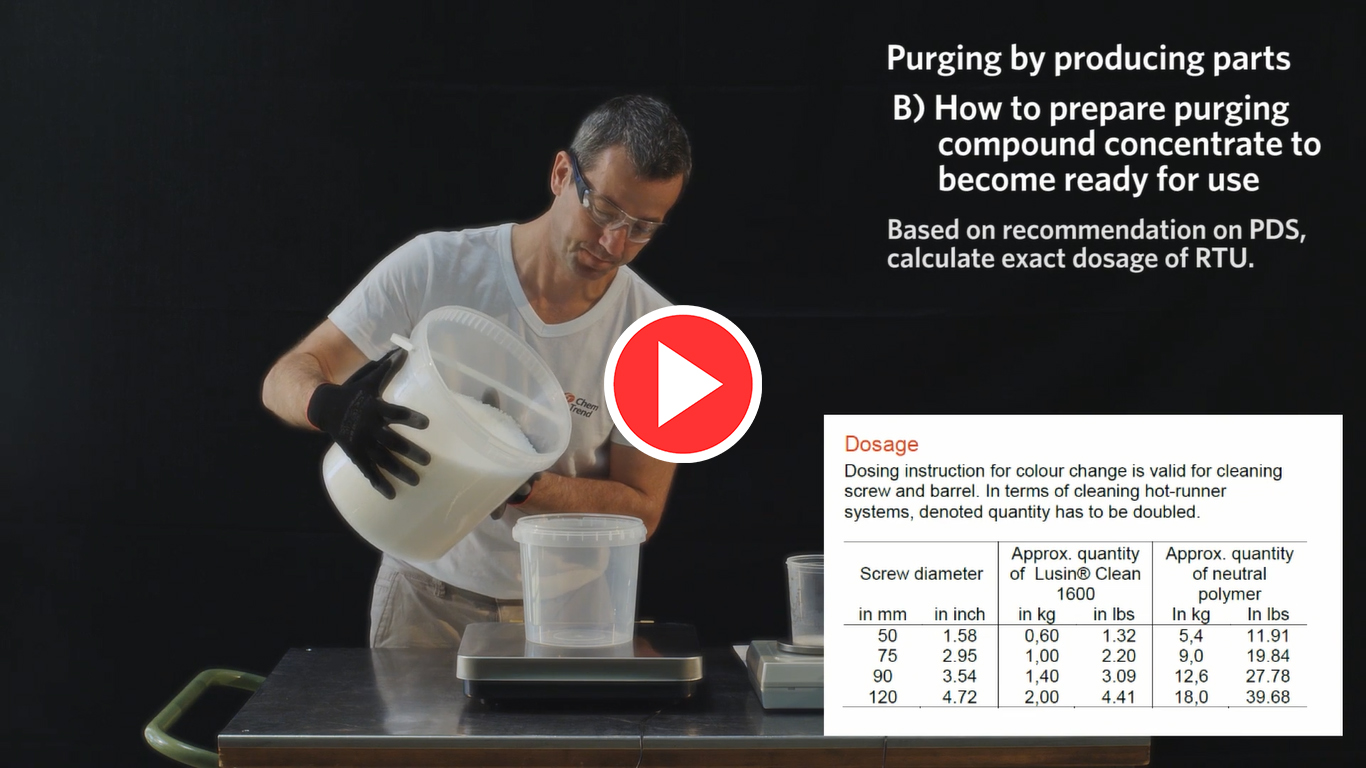

For Injection Moulding :

- 1 full barrel for color changes and black specks removal with Injection molding machines

- ½ full barrel for shut-downs with Injection molding machines

For Extrusion :

- 1 – ½ full barrel for color changes and black specks removal with Extruders machines

- 1 full barrel for shut down with extruders

For Blow Moulding :

- 1 full barrel for color changes and black specks removal with Blow Molding machines.

- ½ full barrel for shut down with blow moulding.

Product description:

Lusin Clean 1010 is a high-quality purging compound that is specifically designed for the processing of polymethylmethacrylates (PMMA) in injection molding machines. It is a ready-to-use compound that is composed of top-grade thermoplastic resins and highly efficient cleaning additives, without containing any abrasives. Lusin Clean 1010 is miscible with PMMA, without leaving any milky traces, and can be used for color and material change, and for the removal of black spot contaminations and carbon residues.

Procedure and usage instructions:

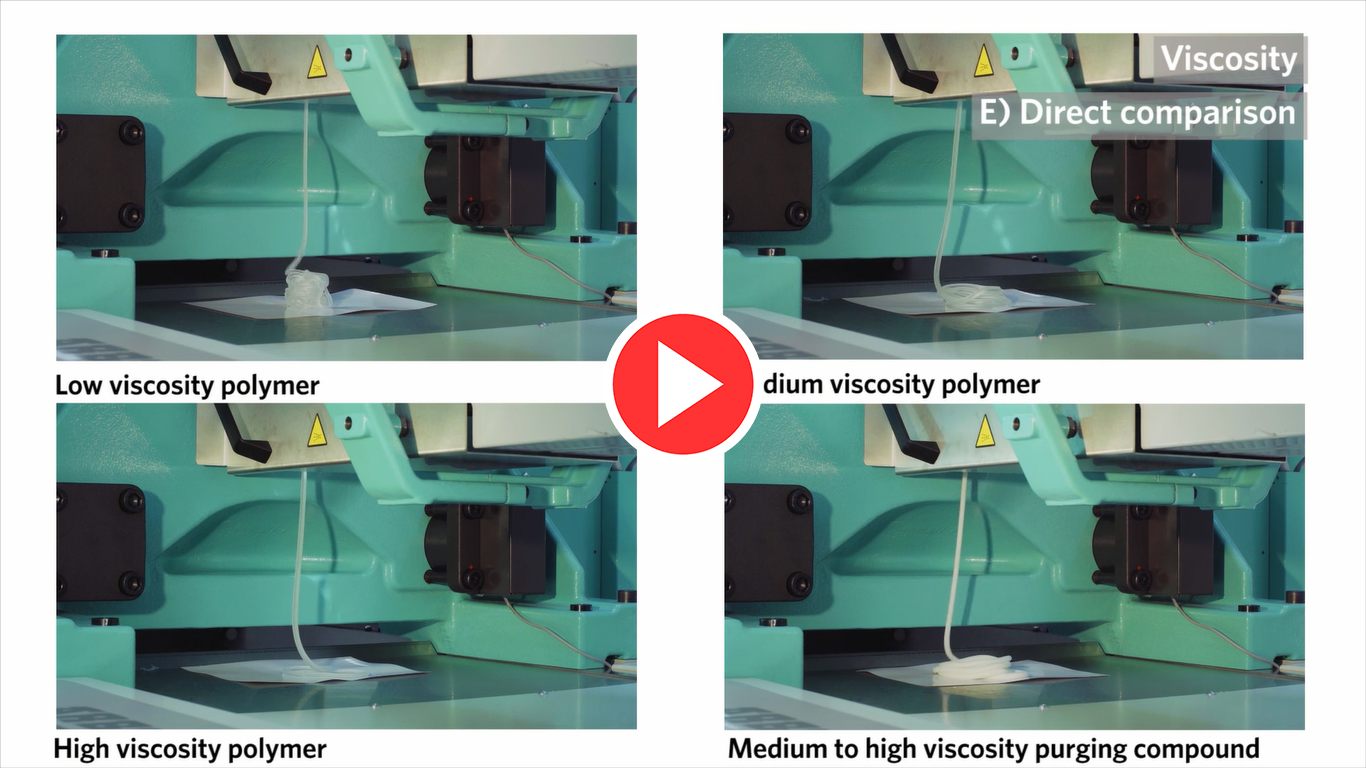

To use Lusin Clean 1010, simply apply the compound to the machine's hot-runner systems, screw, barrel, nozzle, and gate for PMMA processing. The recommended processing temperature for this purging compound is up to 300°C (572°F). Lusin® Clean 1010 does not generate any smell during application, and it does not contaminate the following parts.

Benefits:

- Lusin Clean 1010 is a dedicated purging compound for cleaning injection molding machines that process PMMA, providing high efficiency in removing residues and encrustations.

- Lusin Clean 1010 is economic due to low consumption, making it a cost-effective option for companies. • During application, there is no smell generated by the purging compound, making it more comfortable for operators.

- The purging compound does not generate any milky traces, ensuring that the resulting products are clean and clear.

- Lusin Clean 1010 is suitable for use on hot-runner systems, making it versatile and adaptable to different machines.

Safety information:

Lusin Clean 1010 is a safe purging compound for use in injection molding machines, with no hazardous components or materials that can harm operators or the environment. However, proper handling and storage procedures must be followed, and the material safety data sheet (MSDS) must be consulted before use.

Conclusion:

Lusin Clean 1010 is a reliable and efficient purging compound that is specifically designed for cleaning injection molding machines that process PMMA. It offers a range of benefits, including high efficiency, low consumption, no smell, and no milky traces, making it a cost-effective and versatile option for companies. With its high-quality formulation and easy application process, Lusin Clean 1010 is an ideal choice for businesses that require a top-grade purging compound.

| Resin | Suitable |

|---|---|

| Polyolefins | |

| Polystyrene and Copolymers | |

| Engineering Plastics: PMMA | ++ |

| High Temperature Thermoplastics (e.g. PEEK, PPS, PSU) |

|

| Thermoplastic Elastomers and Urethanes |