Lusin Clean 1500

Code: LU1500

Description - Lusin Clean 1500 is a highly concentrated purging compound that is specially developed for the processing of Polycarbonate. The purging compound consists of high quality thermoplastic resins as well as highly efficient cleaning additives and does not contain abrasives. The product is completely miscible with Polycarbonates and does not generate any milky traces. This has to be mixed as one part of purging compound with three parts of unfill resin

Recomended For - Poly Carbonate(PC)

Tempreture Range - Lusin Clean 1500 can be used at processing temperatures from 250 °C (482 °F) to 350 °C (662 °F).

For Injection Moulding :

- 1 full barrel for color changes and black specks removal with Injection molding machines

- ½ full barrel for shut-downs with Injection molding machines

For Extrusion :

- 1 – ½ full barrel for color changes and black specks removal with Extruders machines

- 1 full barrel for shut down with extruders

For Blow Moulding :

- 1 full barrel for color changes and black specks removal with Blow Molding machines.

- ½ full barrel for shut down with blow moulding.

Product Description:

Lusin Clean 1500 is a highly concentrated purging compound that has been specially formulated for use during the processing of Polycarbonate. The purging compound is made up of top-quality thermoplastic resins as well as highly efficient cleaning additives, and does not contain any abrasives. It is completely miscible with Polycarbonates and does not leave any milky traces.

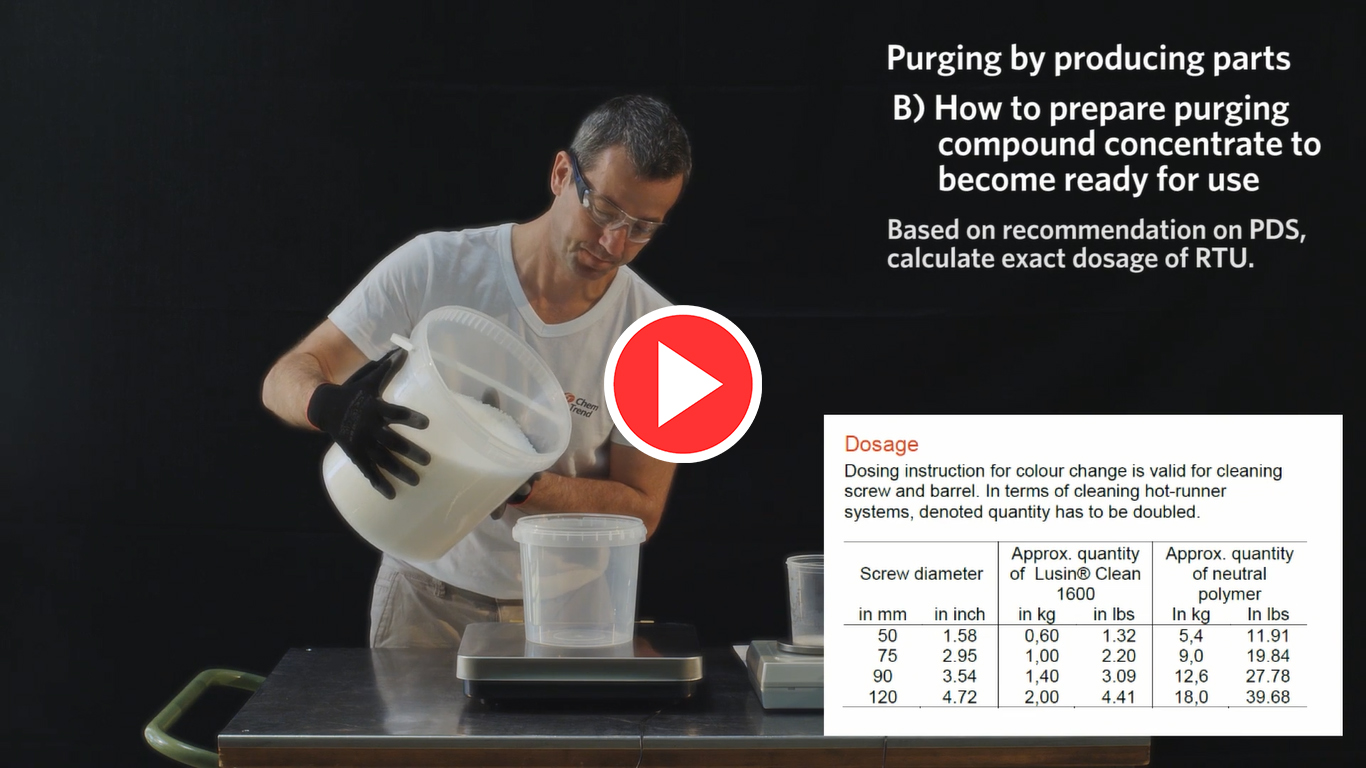

Procedure and Usage Instructions:

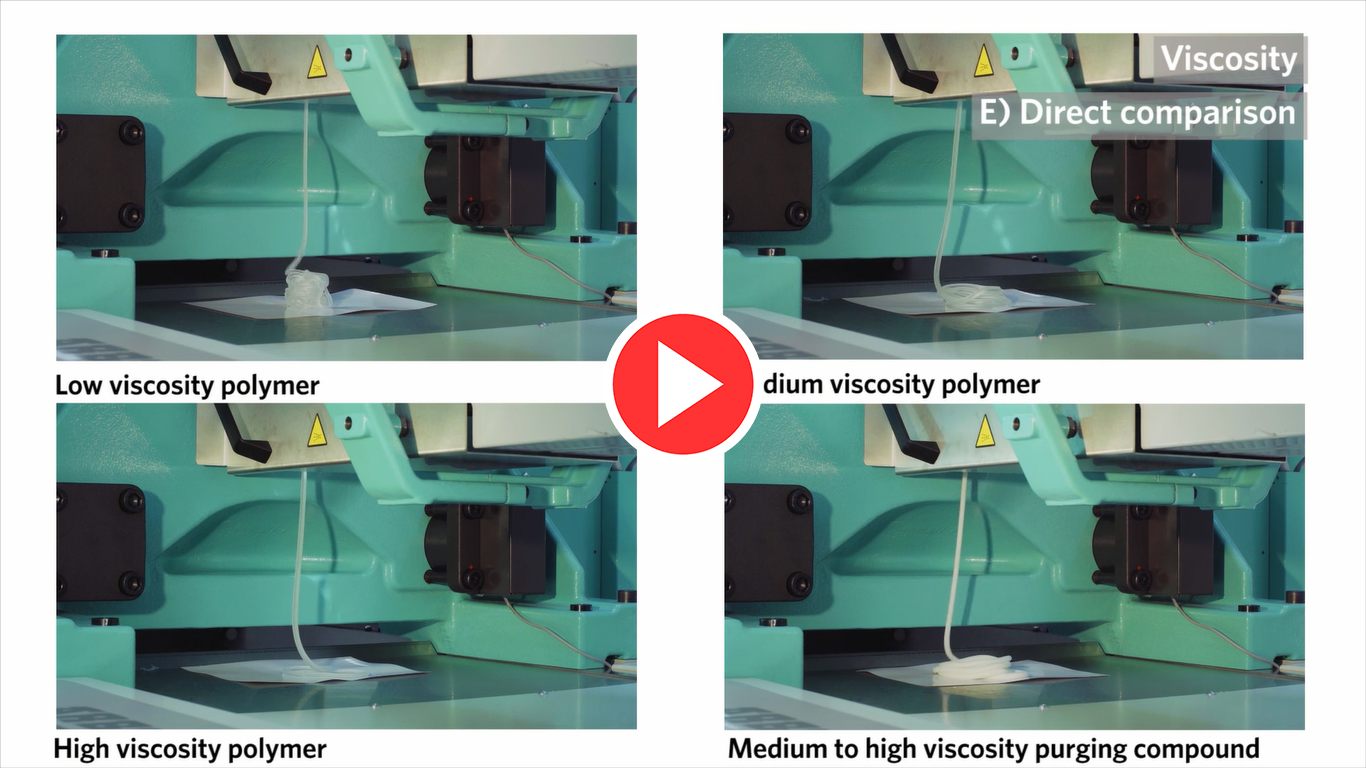

To use Lusin Clean 1500, mix one part of the purging compound with three parts of unfilled resin. The product can be used for cleaning injection molding machines processing Polycarbonates. It is suitable for use at processing temperatures ranging from 250 °C (482 °F) to 350 °C (662 °F). The purging compound can be used for color and material changes as well as for the removal of black specs and carbon residues, particularly on transparent parts.

Benefits:

Lusin Clean 1500 offers several benefits, including its suitability for the cleaning of injection molding machines processing Polycarbonates, up to a processing temperature of 350 °C (662 °F). It is also economical due to low consumption, generates no smell during application, and does not contaminate the following parts. Additionally, it can remove residues and encrustations and does not leave any milky traces. Lusin Clean 1500 is also suitable for use on hot-runner systems.

Safety Information:

Always follow the recommended procedures for the use of Lusin Clean 1500. Avoid contact with skin and eyes, and keep the product away from heat sources and flames. Store in a cool and dry place, and keep away from children.

Conclusion:

Lusin Clean 1500 is a highly efficient and effective purging compound that is specifically designed for use in injection molding machines processing Polycarbonates. It offers several benefits, including low consumption, no contamination, and the ability to remove residues and encrustations. The product is easy to use and generates no smell during application, and is safe for both operators and equipment. You can contact the manufacturer or supplier to learn more about Lusin Clean 1500 and how it can benefit your injection molding processes.

| RESIN | SUITABLE |

|---|---|

| Amorphous resins (especially developed for PC) | ++ |

| Crystalline resins | |

| PA, POM | |

| PET | |

| Polyolefins | |

| PS | |

| TPE-TPR | |

| High-temperature engineering resins | |

| PVC | |

| TPU | |

| Transparent polyamides, CA, CAB, when switching from any resin to PMMA |

|

| When switching from any resin to PC | |

| When switching from any resin to PMMA |