Ultra Purge 2610 (2151)

Code: UP2610

Description - Ultra Purge 2610 is a ready-to-use granular purging compound for screw, barrel, nozzle, hot-runner and gate of injection molding machines processing thermoplastic resins. Ultra Purge 2610 can also be used for cleaning sheet extrusion lines and blow molding machines with and without accumulator. The purging compound consists of high quality thermoplastic resins as well as highly efficient cleaning additives and does not contain abrasives. According to FDA regulations (21 CFR) all components of the formulation of Ultra Purge 2610 are permitted for direct or indirect food contact.

Redomended For - Polymers includes HDPE, LDPE, PP, POM, PVC, TPU, TPE, ABS, Nylon Etc.

Tempreture Range - Ultra Purge 2610 can be used at processing temperatures from 160°C (320°F) to 350°C (662°F).

For Injection Moulding :

- 1 full barrel for color changes and black specks removal with Injection molding machines

- ½ full barrel for shut-downs with Injection molding machines

For Extrusion :

- 1 – ½ full barrel for color changes and black specks removal with Extruders machines

- 1 full barrel for shut down with extruders

For Blow Moulding :

- 1 full barrel for color changes and black specks removal with Blow Molding machines.

- ½ full barrel for shut down with blow moulding.

Product Description:

Ultra Purge 2610 is a high-quality, granular purging compound designed for use in screw, barrel, nozzle, hot-runner, and gate of injection molding machines. It is also suitable for cleaning sheet extrusion lines and blow molding machines. The purging compound contains top-notch thermoplastic resins and effective cleaning additives without any abrasives. It is compliant with FDA regulations (21 CFR) and all components of the formulation are permitted for direct or indirect food contact.

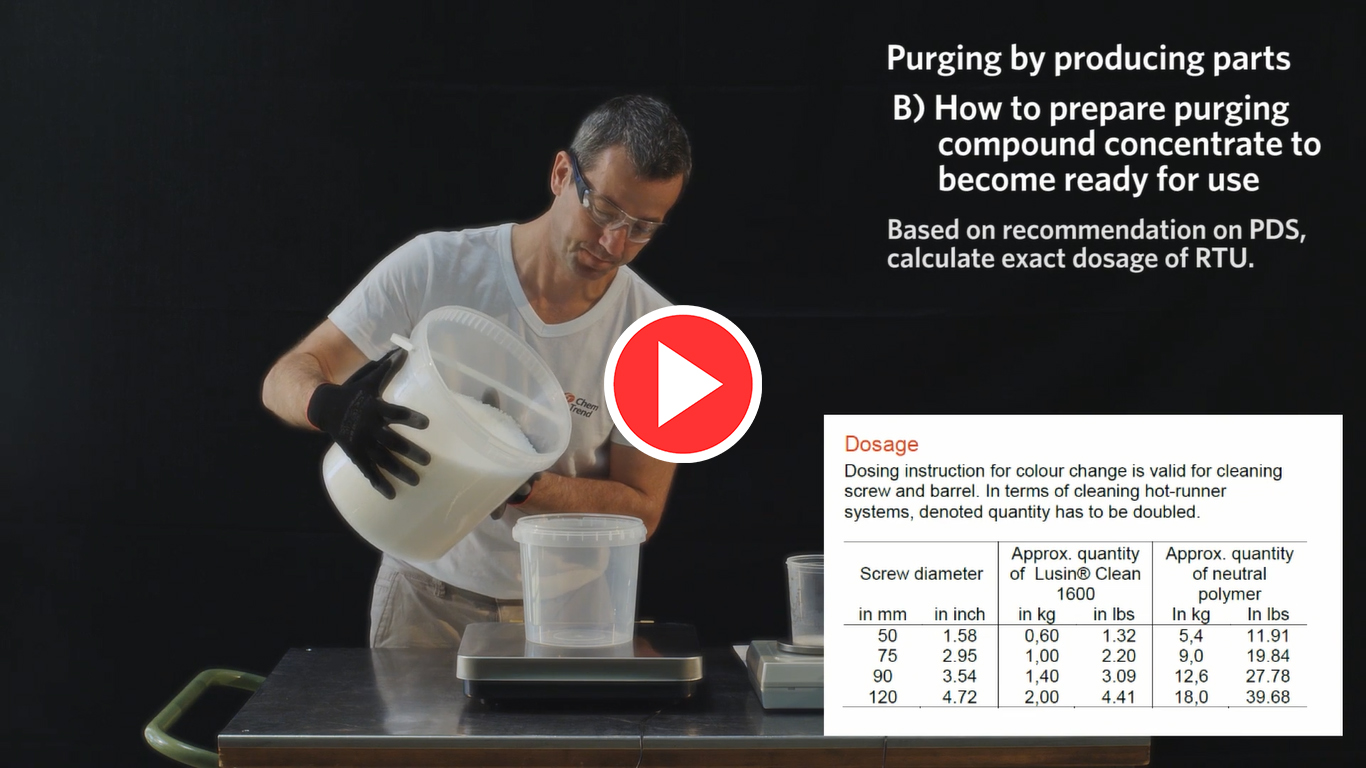

Procedure and Usage Instructions:

Ultra Purge 2610 is a ready-to-use purging compound that requires no mixing. It can be used directly for cleaning conductive resins in injection molding and extrusion applications. It is recommended for color and material changes, removal of black spots, carbon residues, and shut-downs. The purging compound can be used at processing temperatures ranging from 160°C (320°F) to 350°C (662°F).

Benefits:

Ultra Purge 2610 offers high efficiency and a rapid cleaning effect, making it an excellent choice for color and material change as well as the removal of black spots, carbon residues, and shut-downs. It is easy to use and operator and equipment safe, and it offers a wide application range.

Safety Information:

Ultra Purge 2610 is safe to use when handled according to the manufacturer's recommendations. As with any chemical product, it is important to use the product in a well-ventilated area and wear protective equipment such as gloves and goggles.

Conclusion:

Ultra Purge 2610 is a high-quality, ready-to-use purging compound that is effective in cleaning conductive resins in injection molding and extrusion applications. Its high efficiency, rapid cleaning effect, ease of use, operator and equipment safety, and wide application range make it a great choice for color and material changeovers, removal of black spots, carbon residues, and shut-downs.

Serving plastic industries across India including Delhi NCR, Noida, Greater Noida, Ghaziabad, Gurgaon, Manesar, Bhiwadi, Bawal, Neemrana, Jaipur, SIDCUL Haridwar, Rudrapur, Dehradun, Chandigarh, Baddi, Roorkee, Pant Nagar - your trusted manufacturer and supplier Novanative

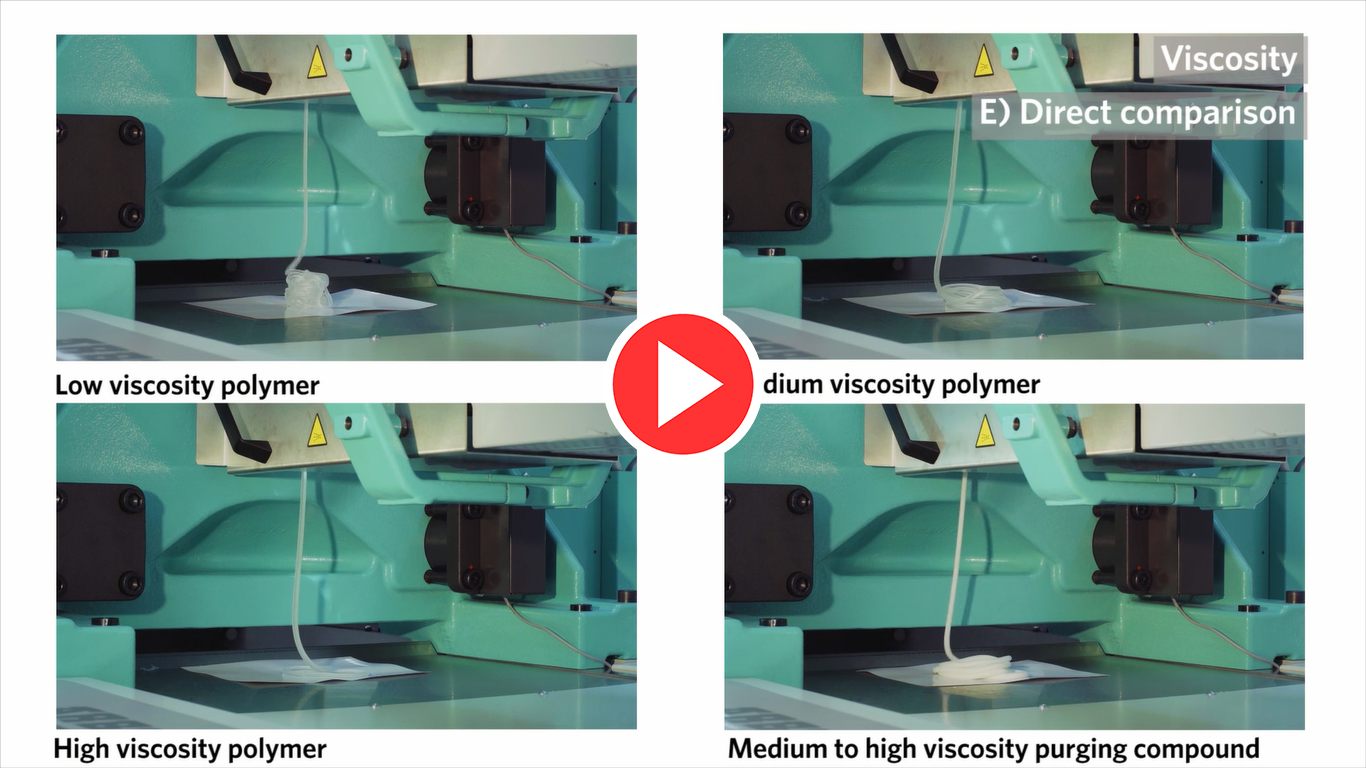

| RESIN | SUITABLE |

|---|---|

| Amorphous resins | |

| Crystalline resins | ++ |

| PA, POM | ++ |

| PET | |

| Polyolefins | ++ |

| PS | + |

| TPE-TPR | + |

| High-temperature engineering resins | |

| PVC | ++ |

| TPU | ++ |

| Transparent polyamides, CA, CAB, when switching from any resin to PMMA |

|

| When switching from any resin to PC | |

| When switching from any resin to PMMA |