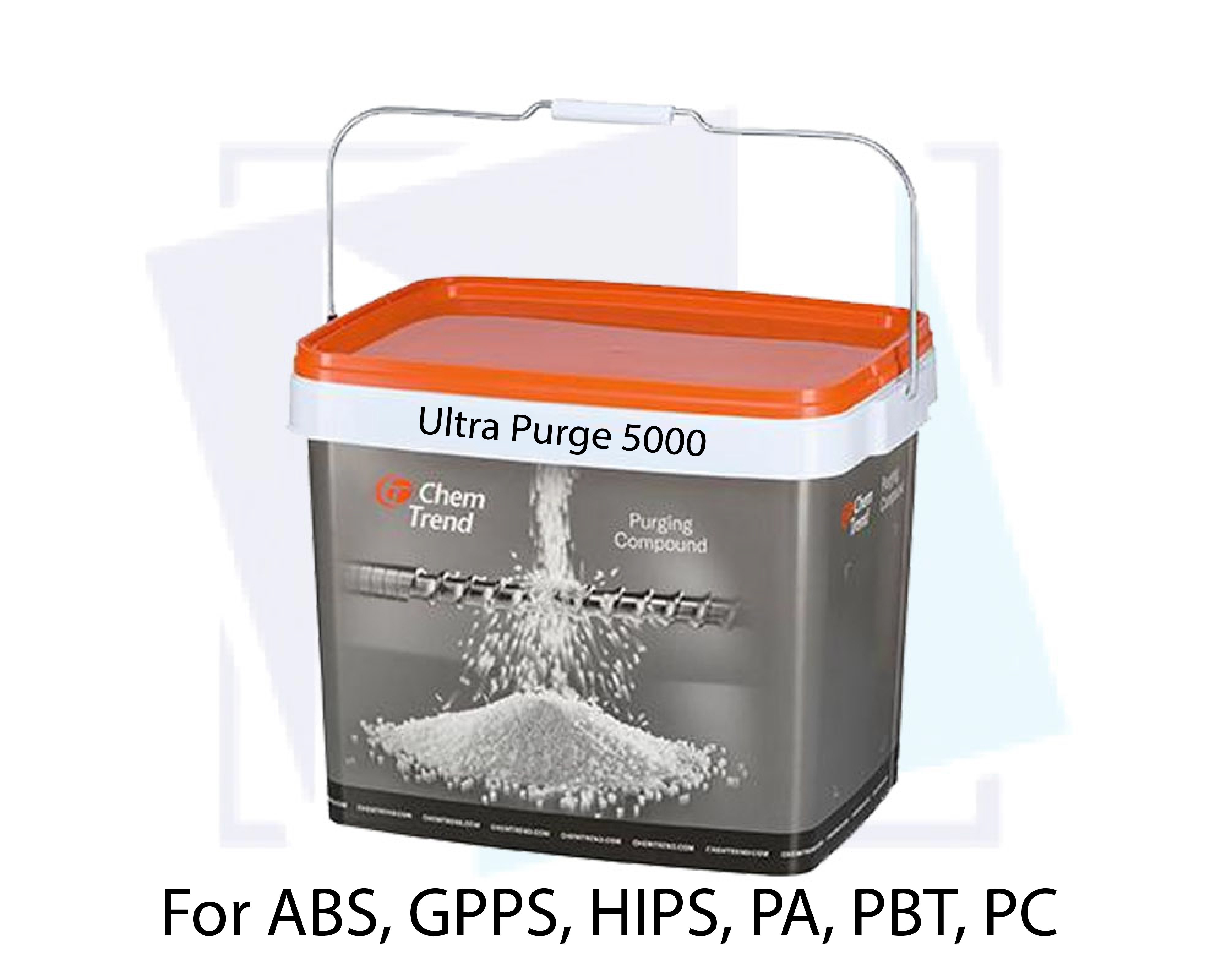

Ultra Purge 5000 (5160)

Code: UP5000

Description - Ultra Purge 5000 is a ready-to-use purging compound. It can be used for cleaning in injection molding, hot-runners, extrusion, and sheet extrusion applications. Ultra Purge 5000 can also be used for the cleaning of screw, barrel, nozzle, hot-runner and gate of injection molding machines processing thermoplastic resins. The purging concentrate consists of highly efficient cleaning additives and does not contain abrasives. It is also refered machine manufactures like huskey sachme etc. According to FDA regulations (21 CFR) all components of the formulation of Ultra Purge 5000 are permitted for direct or indirect food contact.

Recomended For - ABS, GPPS, HIPS, PA, PBT, PC, PET, PMMA, PS, SAN.

Tempreture Range - Ultra Purge 5000 can be used at processing temperatures from 190°C (374°F) to 320°C (608°F).

For Injection Moulding :

- 1 full barrel for color changes and black specks removal with Injection molding machines

- ½ full barrel for shut-downs with Injection molding machines

For Extrusion :

- 1 – ½ full barrel for color changes and black specks removal with Extruders machines

- 1 full barrel for shut down with extruders

For Blow Moulding :

- 1 full barrel for color changes and black specks removal with Blow Molding machines witout accumulator.

- ½ full barrel for shut down with blow moulding

Product Description:

Ultra Purge 5000 is a ready-to-use purging compound specially designed for cleaning purposes in various plastic processing applications. It can be used for cleaning hot-runners, injection molding, extrusion, and sheet extrusion applications. Ultra Purge 5000 consists of highly efficient cleaning additives and is recommended for color and material change as well as for the removal of black spots, carbon residues, and shut-downs.

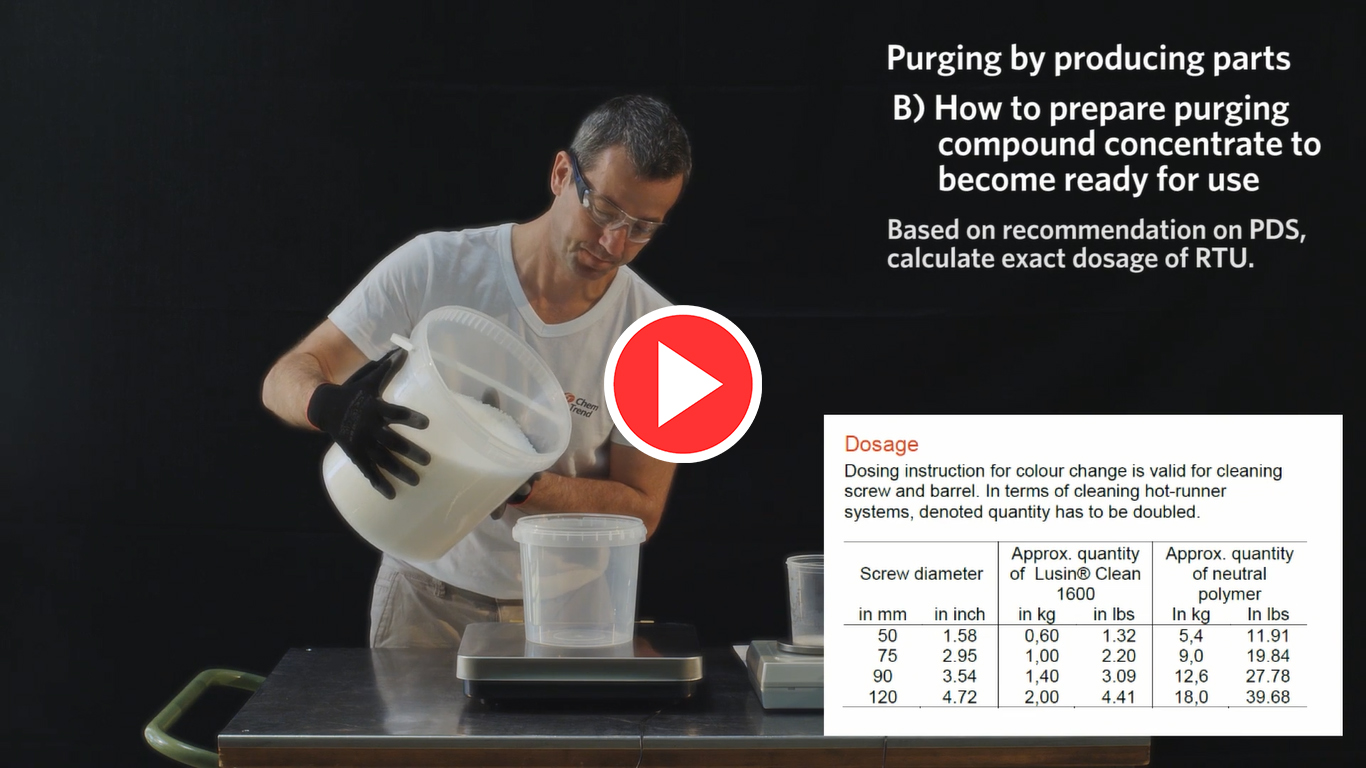

Procedure and Usage Instructions:

The purging compound can be used directly without any need for mixing or dilution. It is recommended to follow the standard procedure for cleaning the equipment, and the compound can be used for cleaning screw, barrel, nozzle, hot-runner, and gate of injection molding machines processing thermoplastic resins. Ultra Purge 5000 can be used at processing temperatures from 190°C (374°F) to 320°C (608°F).

Benefits:

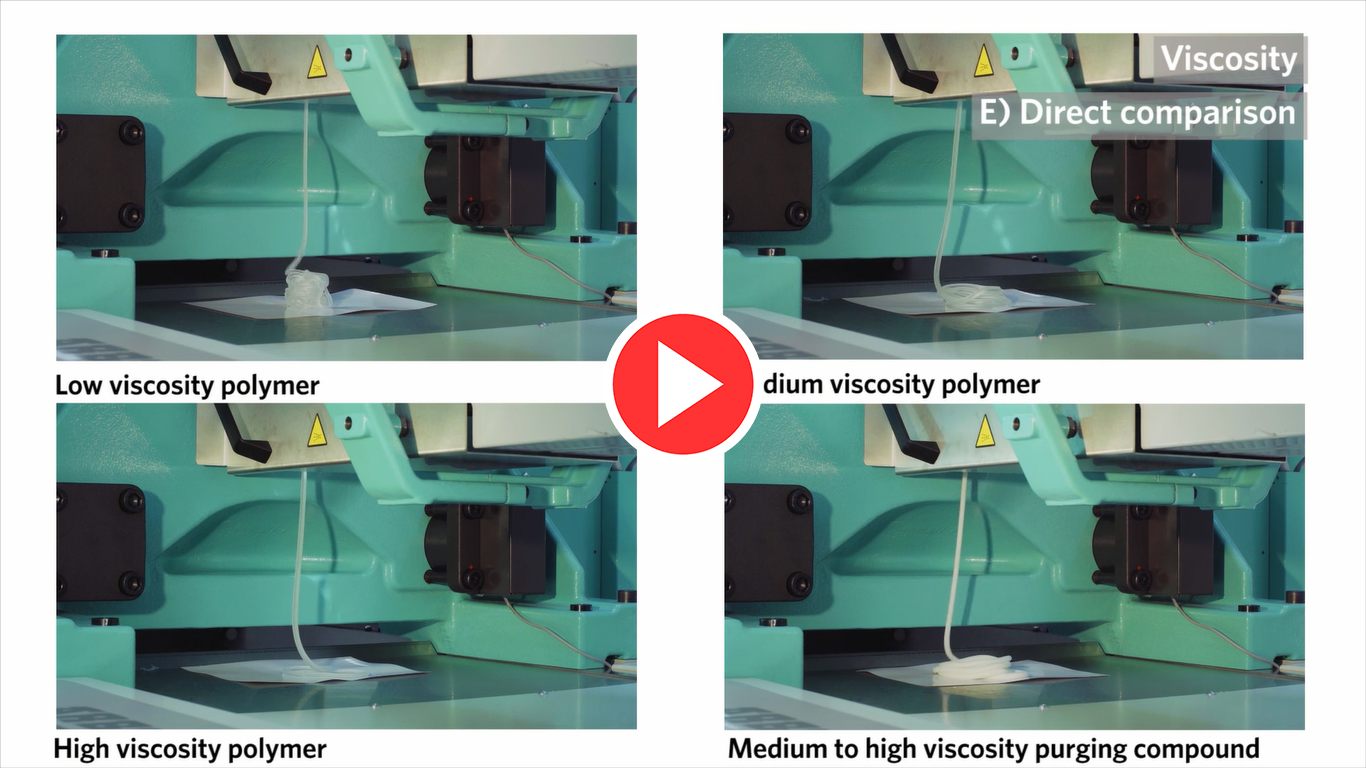

Ultra Purge 5000 offers several benefits such as high efficiency, rapid cleaning effect, easy-to-use procedure, operator and equipment safety, and wide application range. The highly efficient cleaning additives in the grade mixer help in reducing the cleaning time, and the ready-to-use form of the purging compound ensures ease of use and handling.

Safety Information:

Ultra Purge 5000 does not contain any abrasives and is safe for both the operator and the equipment. According to FDA regulations (21 CFR), all components of the formulation of Ultra Purge 5000 are permitted for direct or indirect food contact.

Conclusion:

Ultra Purge 5000 is a highly efficient purging compound that offers quick and easy cleaning of the equipment in plastic processing applications. The ready-to-use form of the mixer having forming agents and mineral make its wide application range for the plastic industry in injection moulding, extrusion, blow moulding.

Serving plastic industries across India including Delhi NCR, Noida, Greater Noida, Ghaziabad, Gurgaon, Manesar, Bhiwadi, Bawal, Neemrana, Jaipur, SIDCUL Haridwar, Rudrapur, Dehradun, Chandigarh, Baddi, Roorkee, Pant Nagar - your trusted manufacturer and supplier Novanative

| RESIN | SUITABLE |

|---|---|

| Amorphous resins | ++ |

| Crystalline resins | |

| PA, POM | + |

| PET | ++ |

| Polyolefins | |

| PS | + |

| TPE-TPR | + |

| High-temperature engineering resins | |

| PVC | |

| TPU | + |

| Transparent polyamides, CA, CAB, when switching from any resin to PMMA |

|

| When switching from any resin to PC | |

| When switching from any resin to PMMA |