Lusin Clean G410

Code: LUG410

Description - Lusin® Clean G 410 is a ready to use granular purging compound for screw, barrel, nozzle and hot-runner of injection moulding machines processing thermoplastic resins. The purging compound consists of high quality thermoplastic resins as well as highly efficient cleaning additives and does not contain abrasives. Lusin® Clean G 410 can be used at operating temperatures in the range between 250°C (482 °F) and 410°C (770 °F) and is suitable for cleaning hot-runners, particularly with external heaters.

Recomended For - PEEK, PPS, PSU

Tempreture Range - Lusin® Clean G 410 can be used at processing temperatures between 250°C (482 °F) and 410°C (770 °F)

For Injection Moulding :

- 1 full barrel for color changes and black specks removal with Injection molding machines

- ½ full barrel for shut-downs with Injection molding machines

For Extrusion :

- 1 – ½ full barrel for color changes and black specks removal with Extruders machines

- 1 full barrel for shut down with extruders

For Blow Moulding :

- 1 full barrel for color changes and black specks removal with Blow Molding machines.

- ½ full barrel for shut down with blow moulding.

Product description:

Lusin® Clean G 410 is a high-quality, ready-to-use granular purging compound designed for cleaning screw, barrel, nozzle, and hot-runner of injection molding machines processing thermoplastic resins. It contains highly efficient cleaning additives and does not contain abrasives. The purging compound is suitable for cleaning hot-runners, particularly with external heaters, and can be used at operating temperatures ranging from 250°C (482°F) to 410°C (770°F).

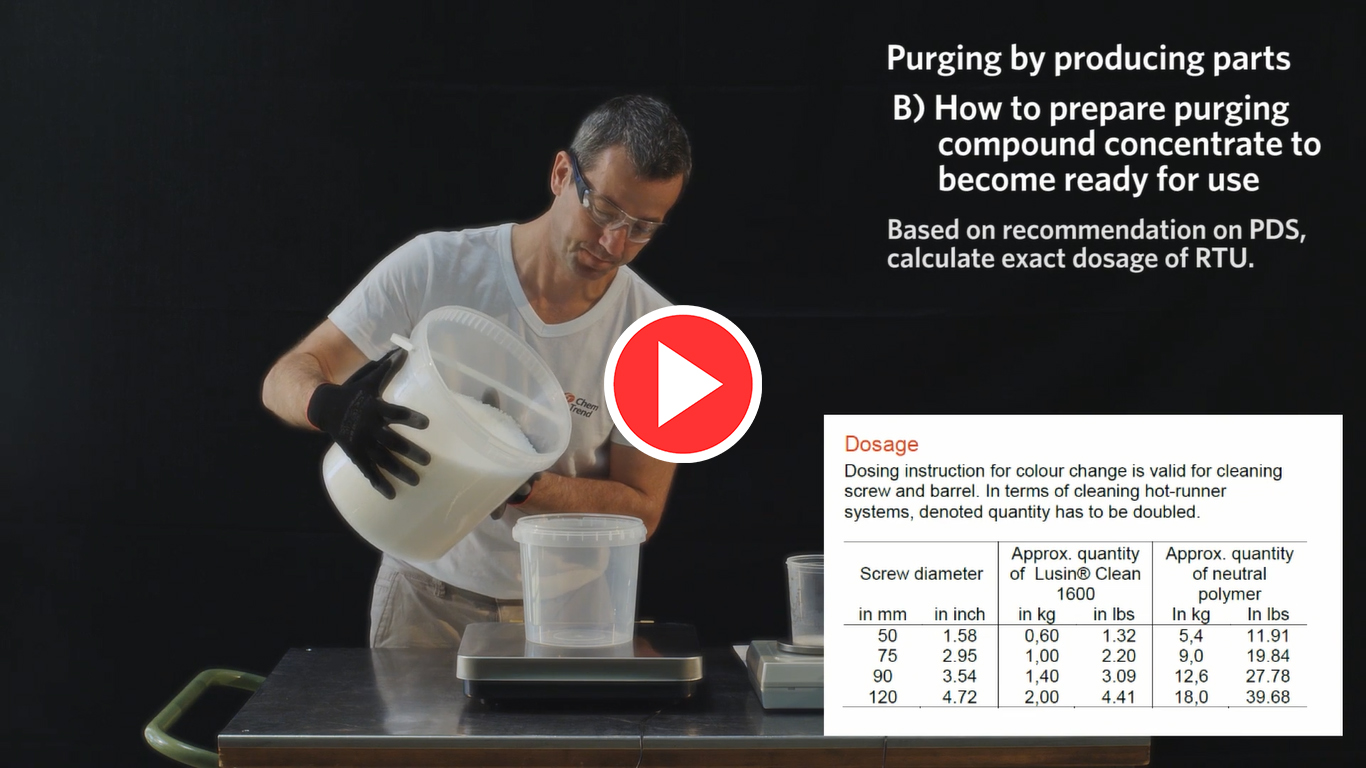

Procedure and usage instructions:

Lusin® Clean G 410 is easy to use. Simply add the purging compound to the machine and run the process until the compound is fully discharged. To achieve optimal results, follow the manufacturer's recommendations and use 2-3 times the amount of the purging compound, depending on the severity of the contamination.

Benefits:

- Suitable for processing temperatures up to 410°C (770°F): Lusin® Clean G 410 can withstand high temperatures, making it ideal for use in injection molding machines operating at high temperatures.

- Economical due to low consumption: The purging compound is designed to minimize consumption and reduce waste, making it a cost-effective solution.

- Fast cleaning process: Lusin® Clean G 410 quickly and effectively removes contaminants, reducing downtime and increasing productivity.

- Suitable for use on hot-runner systems: The purging compound is suitable for cleaning hot-runner systems, particularly those with external heaters, ensuring a thorough and efficient cleaning process.

Safety information:

When handling Lusin® Clean G 410, it is important to follow standard safety procedures, including wearing protective equipment and avoiding contact with the skin and eyes. The purging compound should be stored in a cool, dry place away from direct sunlight, heat sources, and moisture.

Conclusion:

Lusin® Clean G 410 is a highly efficient, cost-effective, and easy-to-use purging compound suitable for cleaning screw, barrel, nozzle, and hot-runner of injection molding machines processing thermoplastic resins. Its fast cleaning process and suitability for high-temperature processing make it an ideal solution for injection molding operations, and its low consumption and suitability for hot-runner systems help reduce waste and increase productivity.

| Resin | Suitable |

|---|---|

| Polyolefins | |

| Polystyrene and Copolymers | |

| Engineering Plastics (e.g. PC, POM, PMMA, PA, PET) |

|

| High Temperature Thermoplastics (e.g. PEEK, PPS, PSU) |

++ |

| Thermoplastic Elastomers and Urethanes |